Sometimes you need a product at your branch which needs to be obtained from another branch. For this purpose you can create an internal order.

When you are relocating products to a mobile pharmacy you would also need to place an internal order to update the batch numbers and expiration dates on the location you distribute the products to.

This article explains how to place an internal order.

Before you start

- Ensure your products are set up with the correct sales, packaging and order units. Be aware of subproducts – they have to be set up correctly as well.

- Set up your current stock and ordering levels.

- When you initially start your internal ordering process we recommend you do this only for part of your stock (e.g. food from just one supplier), and for only one of your stores/locations until you understand the system and all products are set up correctly.

At the bottom of this article, you will find links to related articles to help you with these settings.

Step-by-step instructions

The branch which is requesting products from another location should proceed as follows:

- Go to

> Stock > Create Order

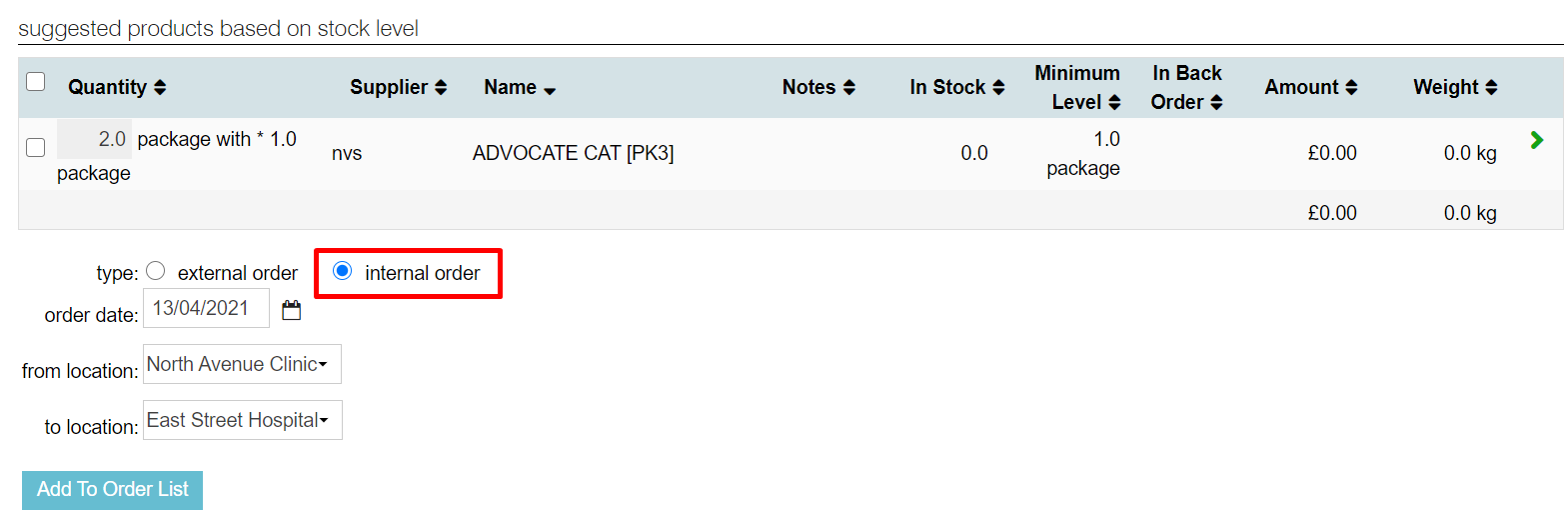

> Stock > Create Order - Select Internal order at the bottom to identify it as a cross-branch order.

This is box titleThis is important! If you don’t do this, the units will not be displayed correctly, changes to the quantities will be erased when you tick “internal order” later and you won’t see the fields “from location” and “to location”.

This is box titleThis is important! If you don’t do this, the units will not be displayed correctly, changes to the quantities will be erased when you tick “internal order” later and you won’t see the fields “from location” and “to location”. - Check the boxes of the products that you wish to request from the other location. Should there not be any products in the list, you need to manually add them. Please refer to the Related articles section for more information.

- Change the quantity if needed. The suggested quantity is a fixed quantity (“order amount”) as set in the product details (

> Products > Products > tab Stock).

> Products > Products > tab Stock). - The fields “from location” and “to location” should be filled correctly but you can adjust them manually if necessary. By default, your current location is entered in the “to location” because you are requesting the products.

- Double check if your order list is complete.

- Click Add to Order List.

More about this

Variations in units and factors for internal orders

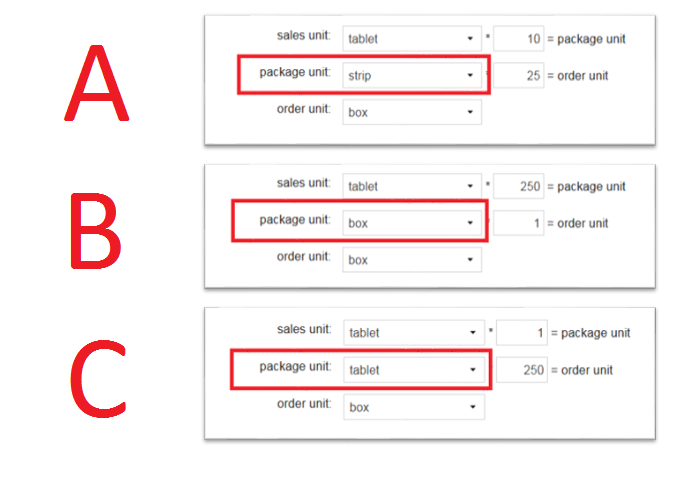

For internal orders to and from locations (e.g. branches or cars) the package unit of a product is essential.

To determine units and factors, Animana advises to use the following technique: first enter the three units (sales unit, package unit, order unit) and then enter the factors to complete the formula. When setting the package unit, decide on the unit that you prefer for internal orders. This can be the same as the sales unit or the order unit.

After entering the units, use the same technique to determine the factors. Here are a few variations:

In all three examples, the sales unit is a tablet and the order unit is a box. All formulas also give the end result of 250 tablets in a box. The only difference is that the package unit is different in each example and the factors are distributed differently.

So, in example A above, we do internal orders per strip, for example B we do internal orders per box, and in example C we do internal orders per tablet.